.

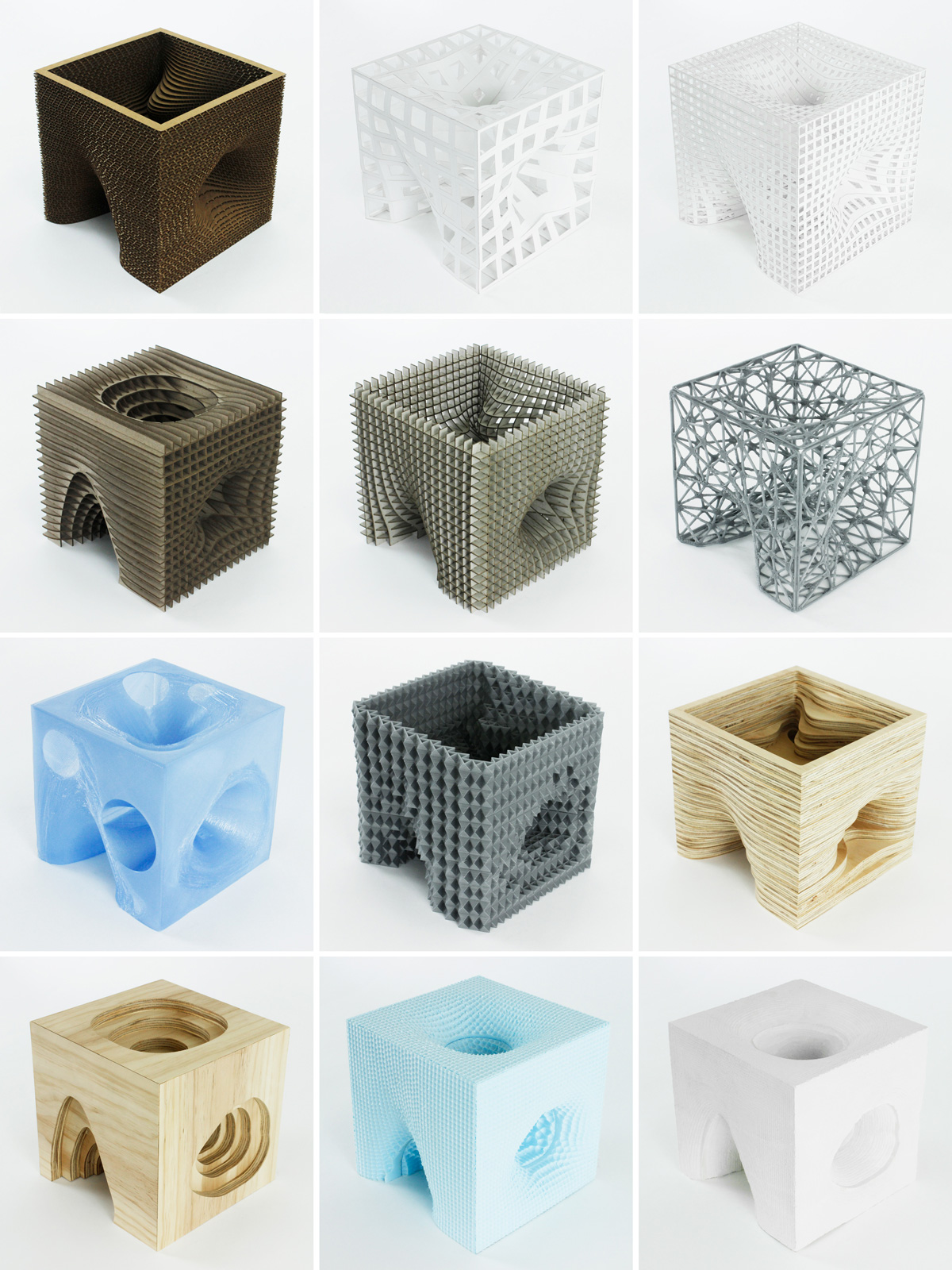

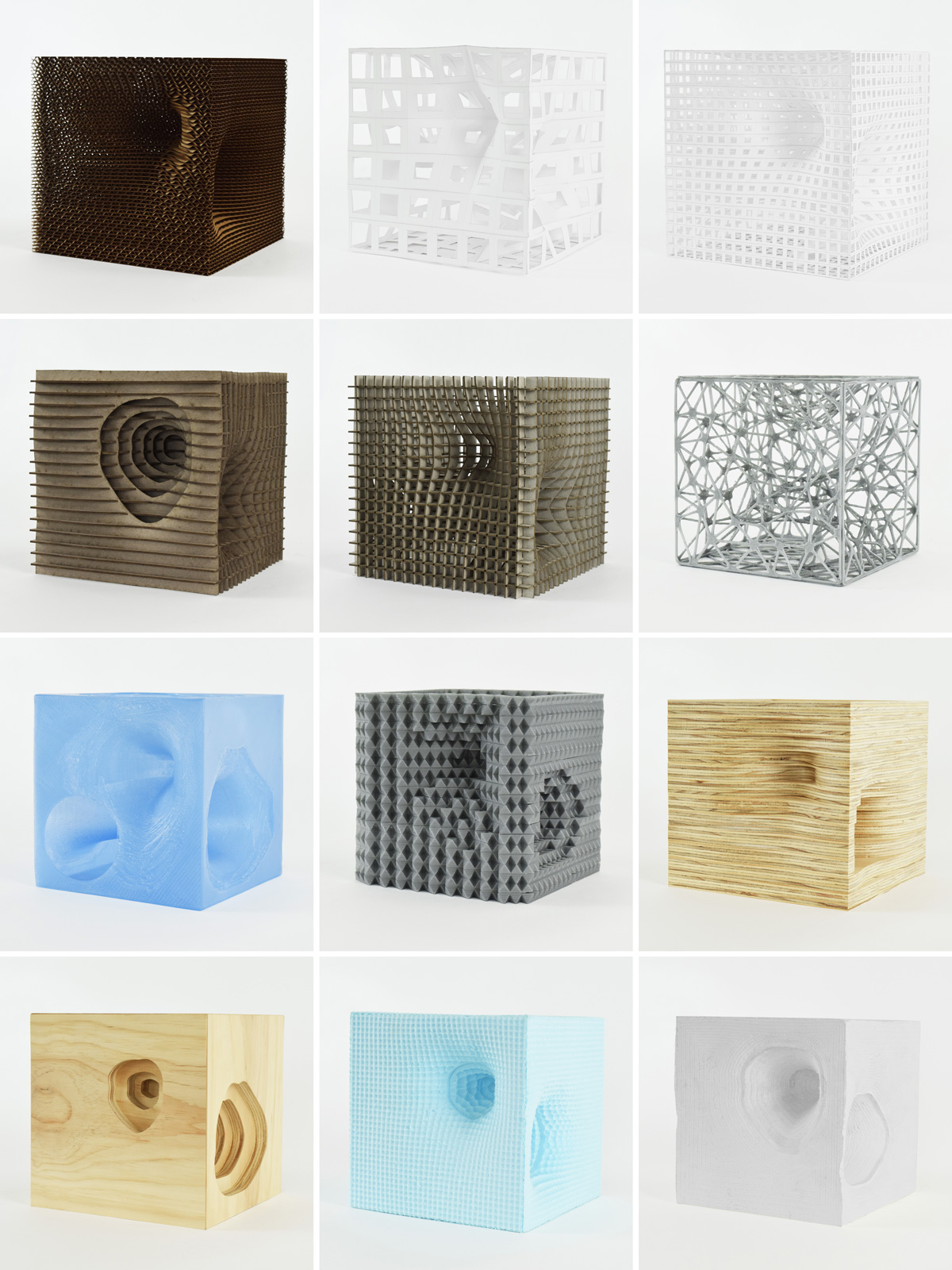

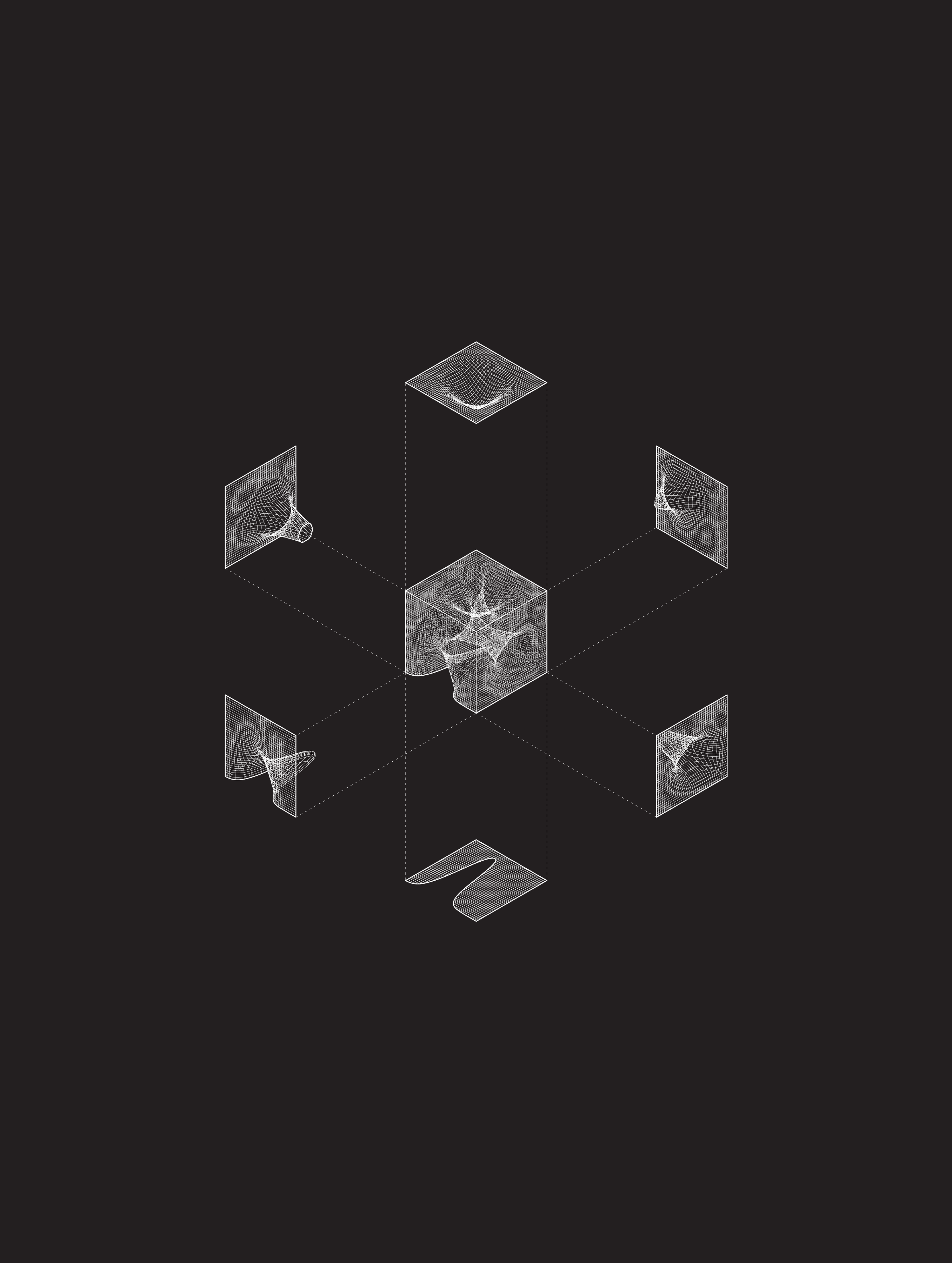

Model Object: 12 Cubes

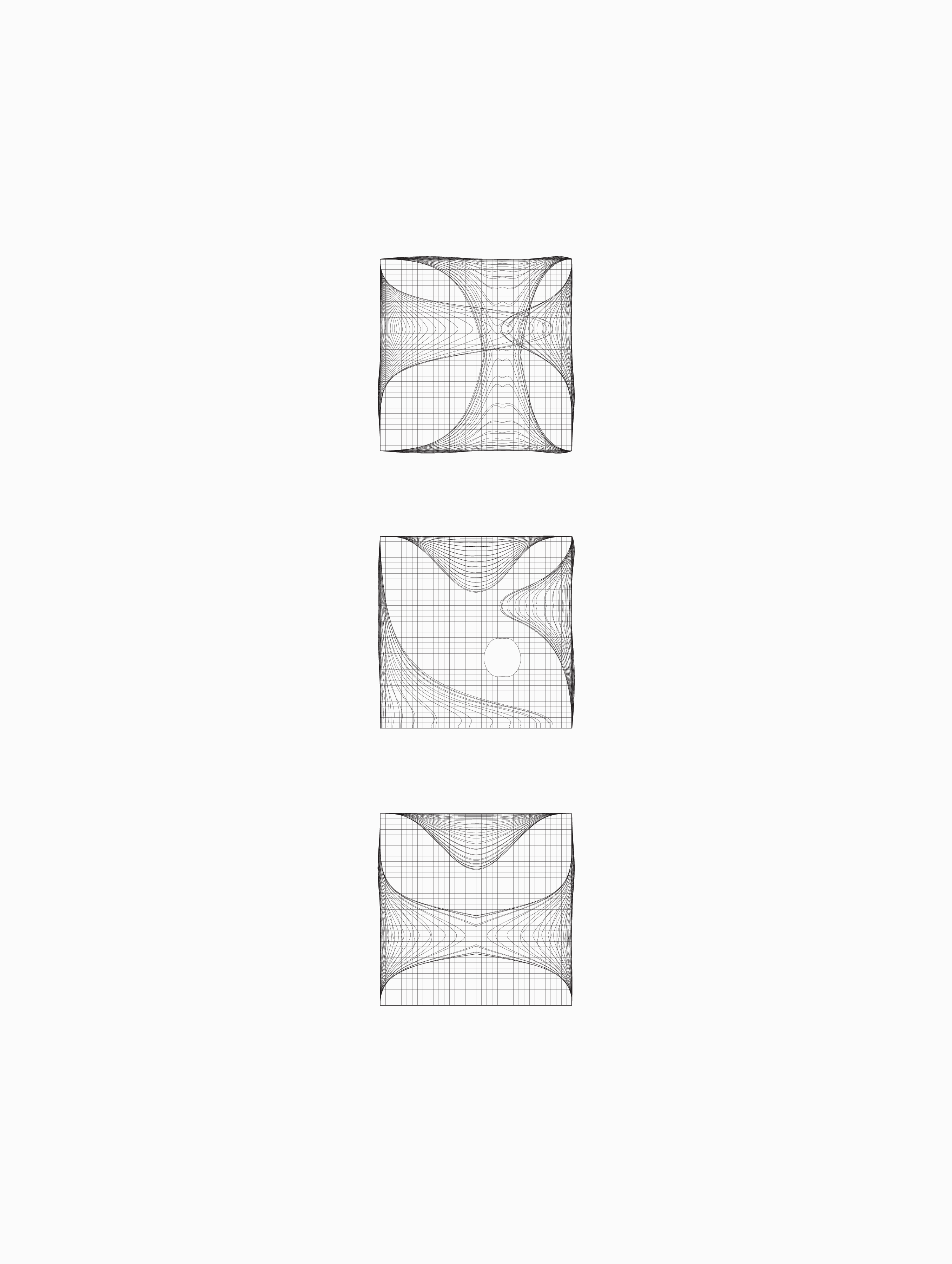

Seminar / Spring 2016 / Year 2 / Rice Architecture / Professors Andrew Colopy + David CostanzaDigital models are central to the design process, more and more displacing drawing as the basis of representation, calculation, and communication. In the context of a material practice, they aid in the simulation of complex behavior, facilitate the description of form, and provide a direct means of machine translation into physical artifacts. Model Object is a serial, comparative investigation: the design of a digital object and its translation into successive material constructs, digitally fabricated and disciplined in geometry, scale, material, and tectonic. The exercise reveals the reciprocal and nonlinear relationship between the digital model and physical object. Nine different methods of fabrication are explored, utilizing seven different materials and three different machining techniques. The implications of the machining technique on the formal reading of the produced object is made apparent, as well as the capability to achieve various resolutions of curvature.

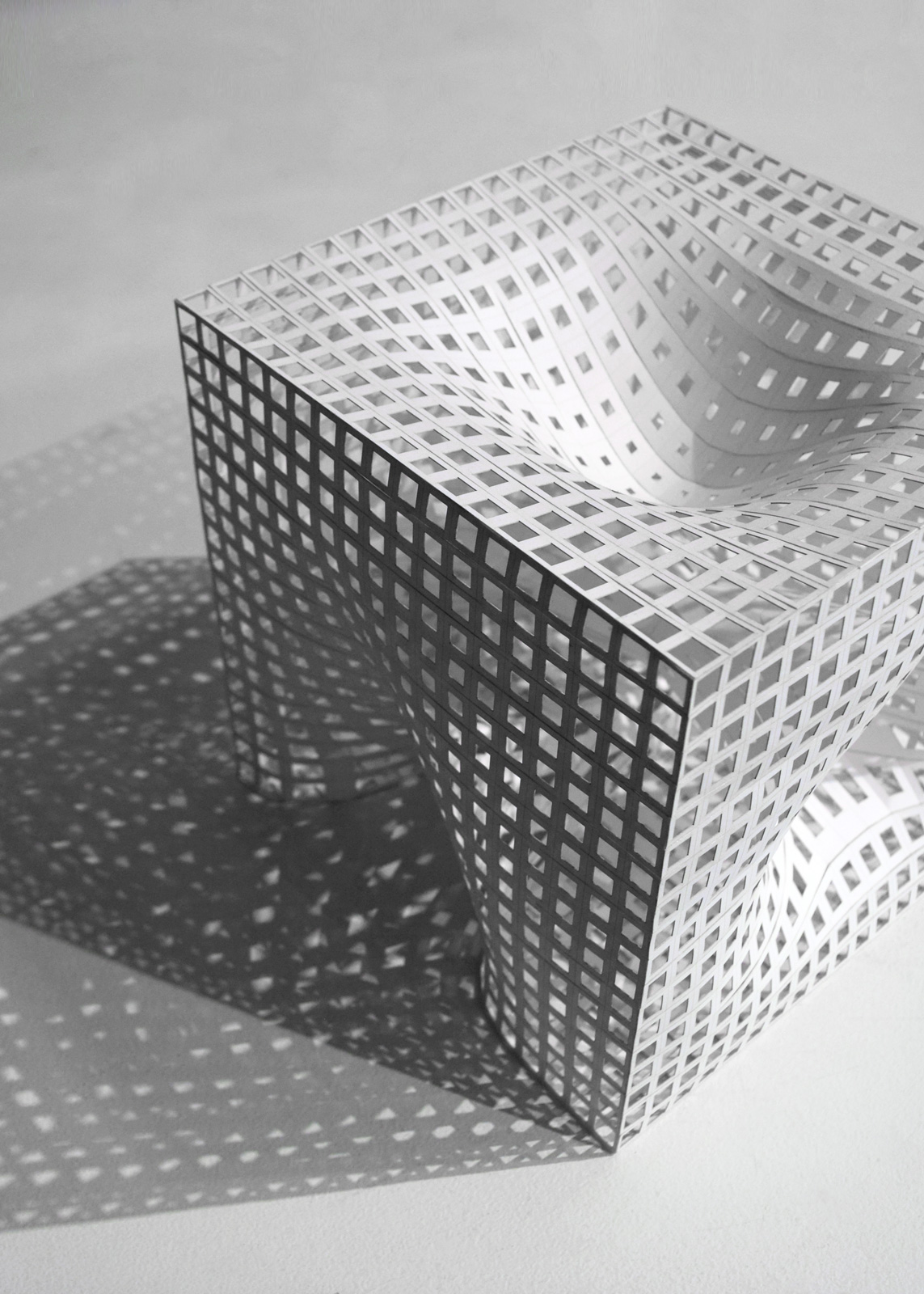

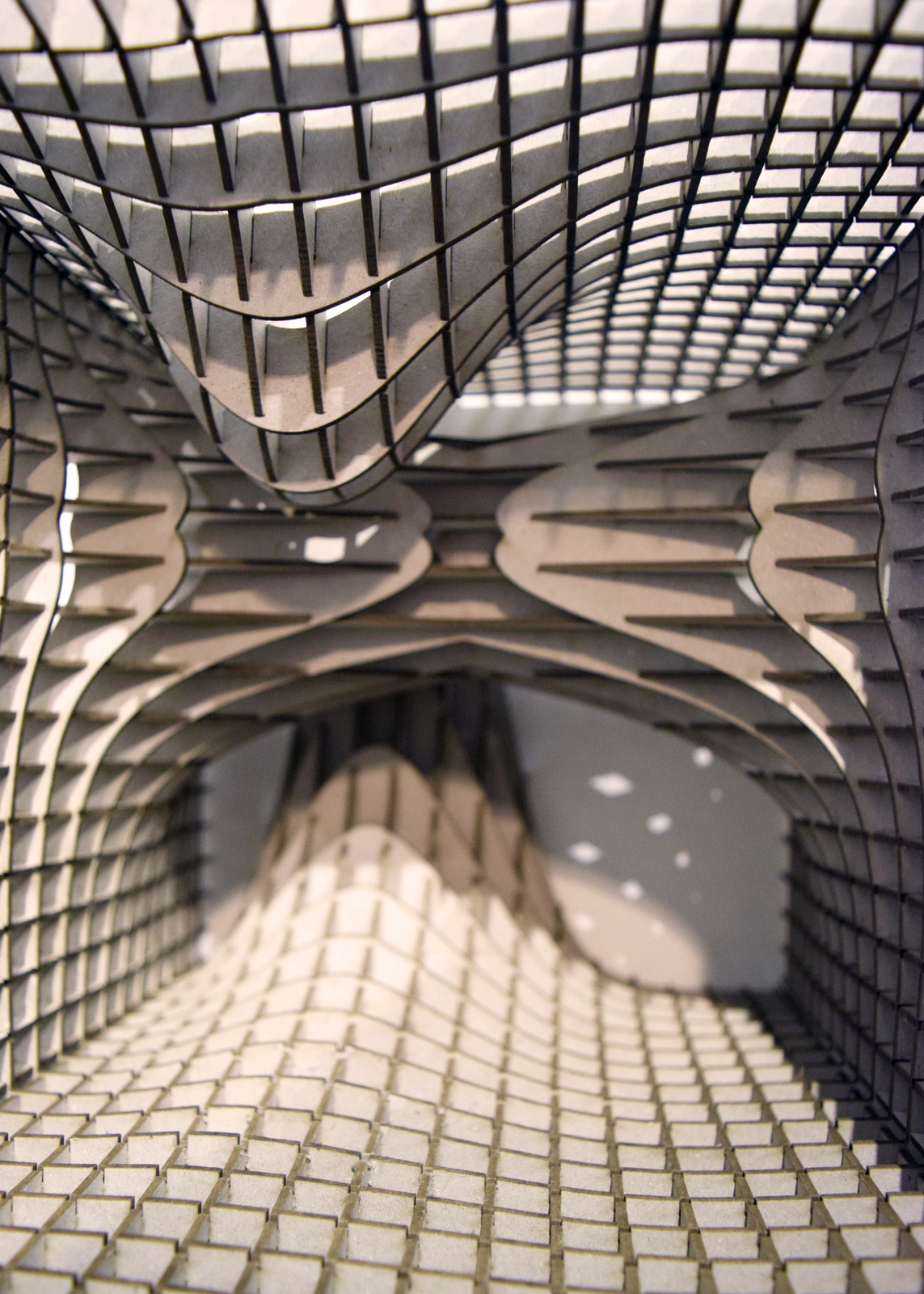

Cutting Fabrication • Laser Cutter

1. Lamination, cardboard

2. Panelization, bristol

3. Waffling, chipboard

1. Lamination, cardboard

2. Panelization, bristol

3. Waffling, chipboard

Additive Fabrication • 3D Printer

4. Skeletal Mesh, filament

5. Thickened Mesh, filament

6. Unit Packing, filament

4. Skeletal Mesh, filament

5. Thickened Mesh, filament

6. Unit Packing, filament

Subtractive Fabrication • CNC Mill

7. Lamination, plywood

8. Surface Milling, foam

9. Casting, concrete

7. Lamination, plywood

8. Surface Milling, foam

9. Casting, concrete