Tile

Project of COBALT OFFICE / Custom model stands for the Rice School of ArchitectureAndrew Colopy, Director

Lara Hansmann, Prototyper

Lara Hansmann, Prototyper

Familiar artifacts in any school of architecture, model stands structure and formalize the act of presentation. Yet their status is secondary, subservient to the work they support. As ancillary objects, they are saddled with the conflicting demands of durability and economy. Most often they are literally heavy, cumbersome, always in the way, and seldom interesting. Enter plastic. Necessarily durable and economical, Tile endeavors to be lighter and more flexible through the unique qualities of plastic.

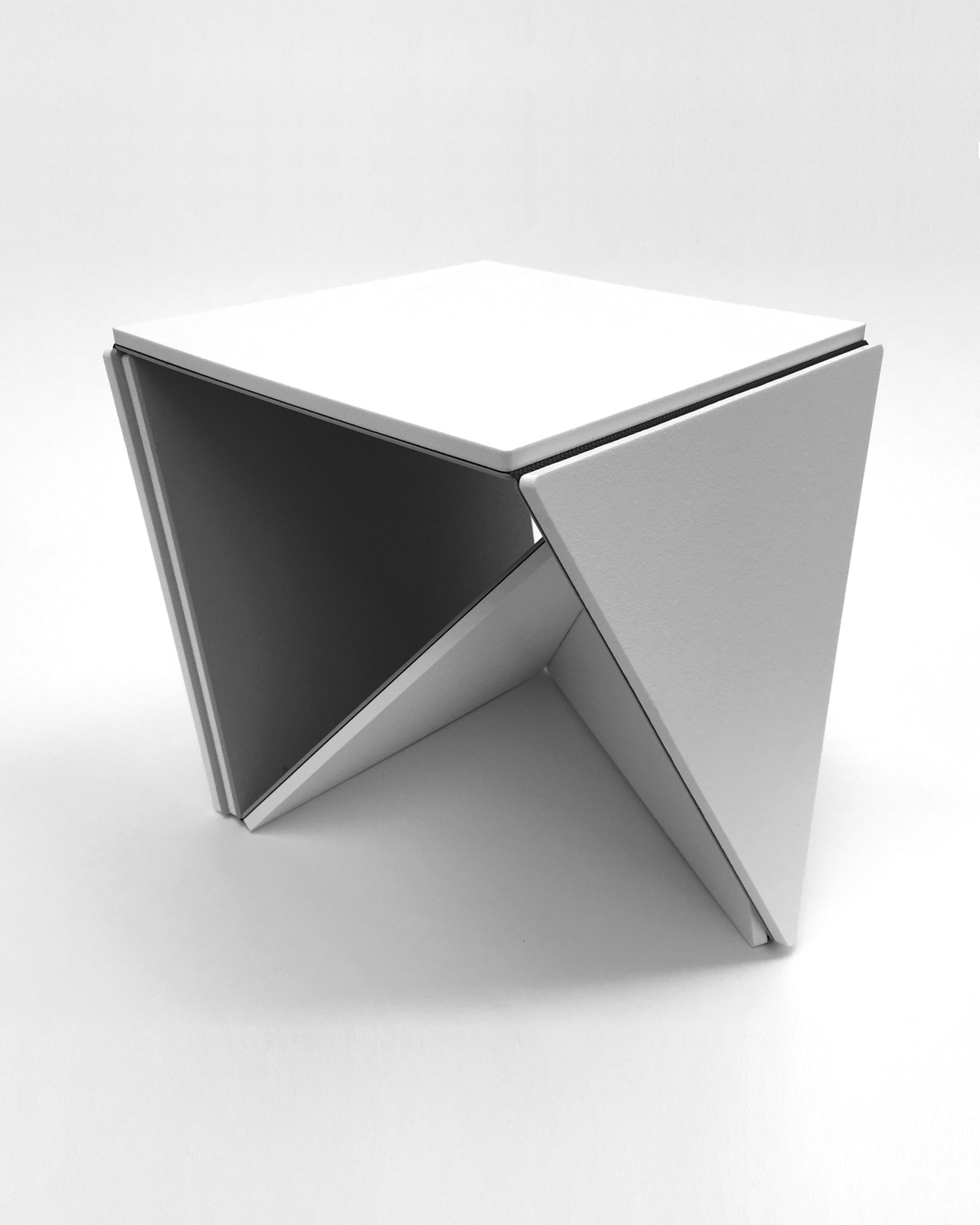

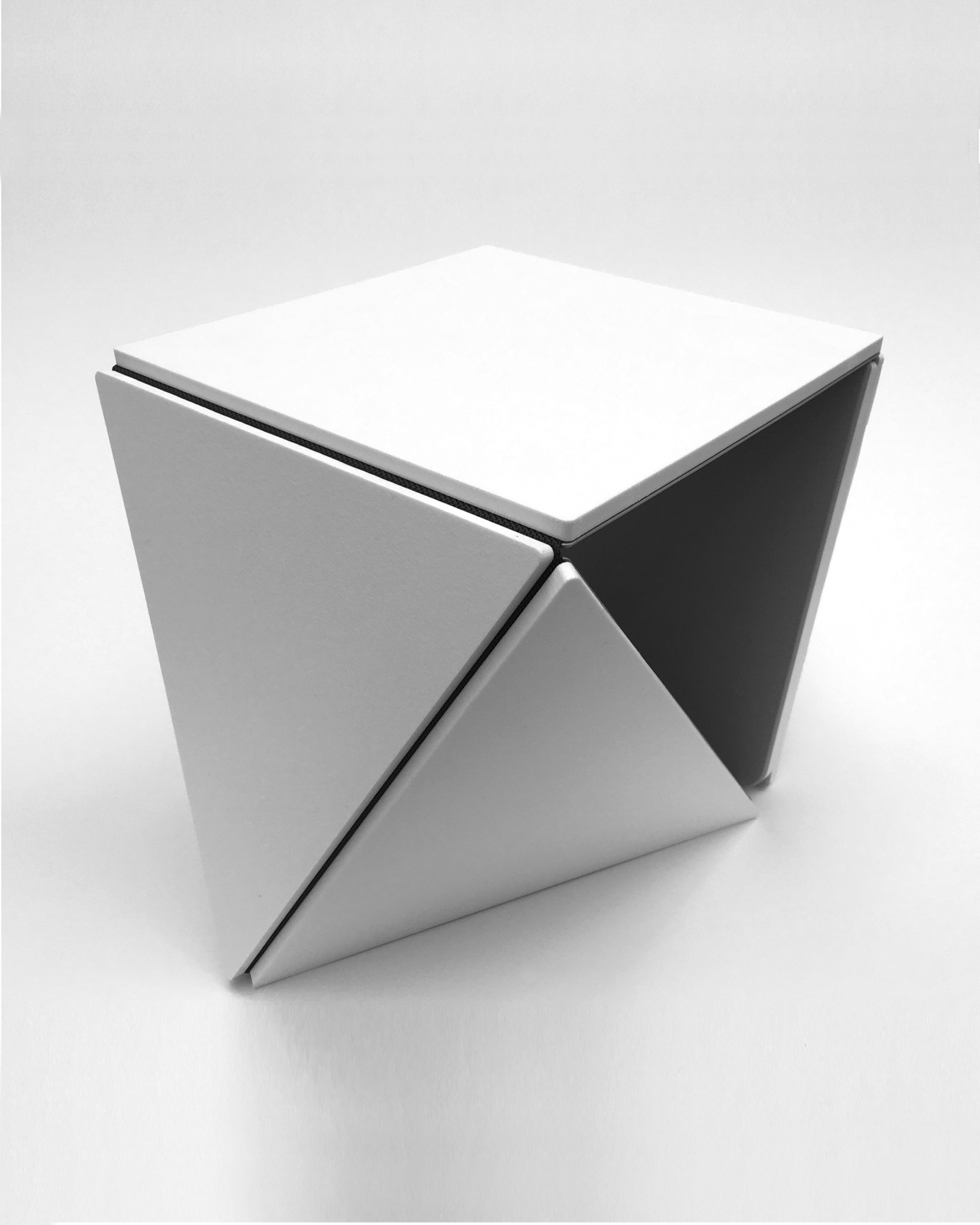

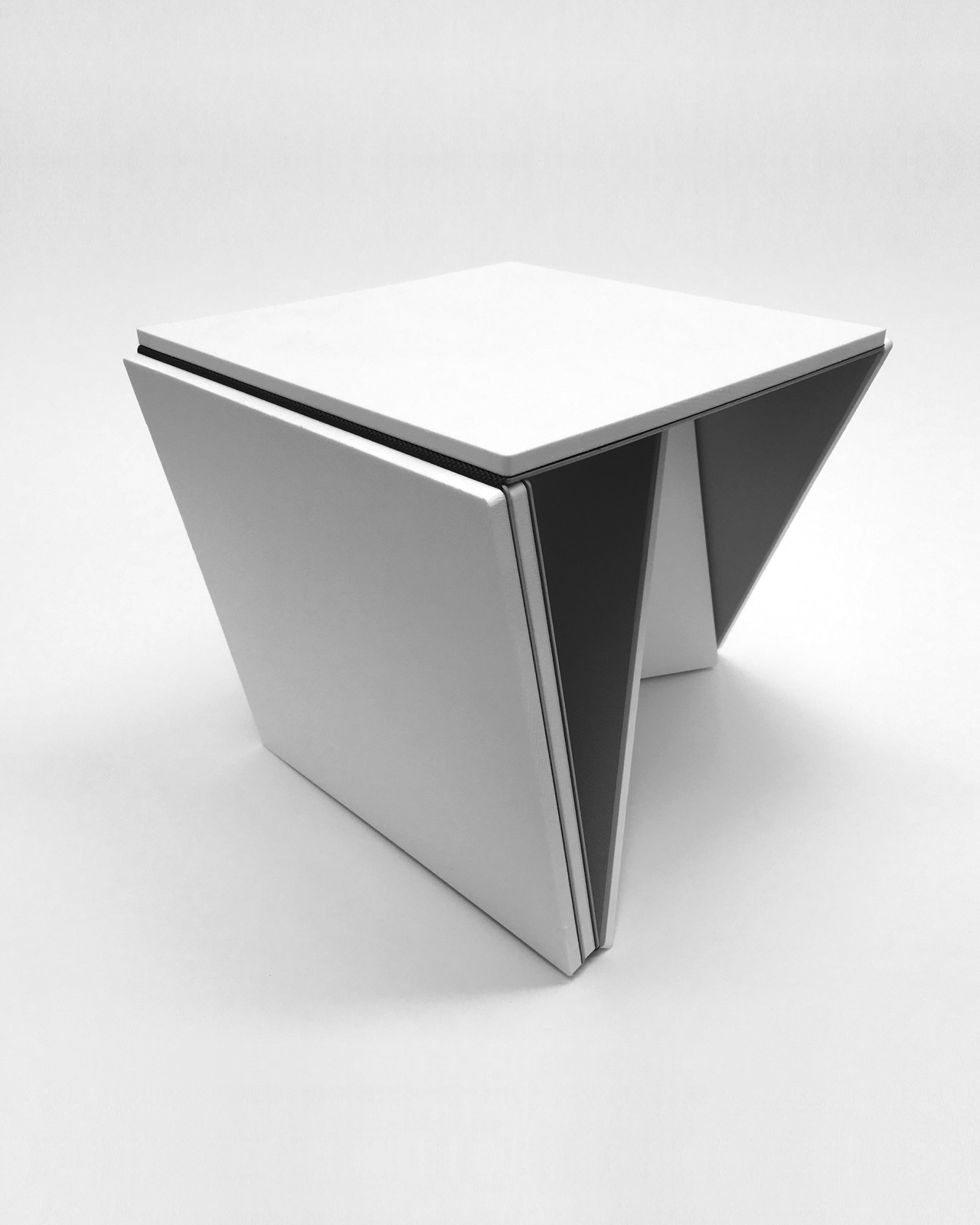

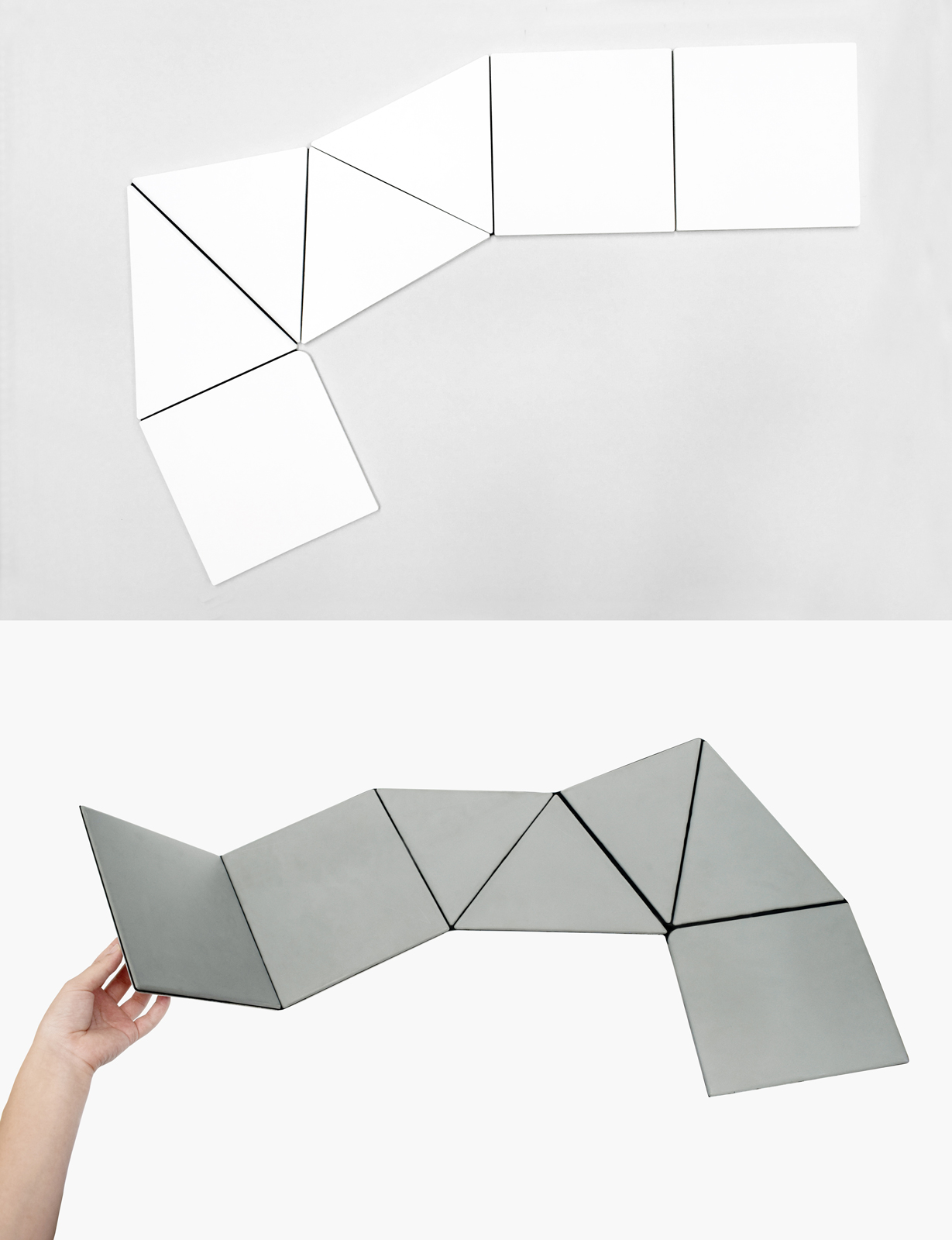

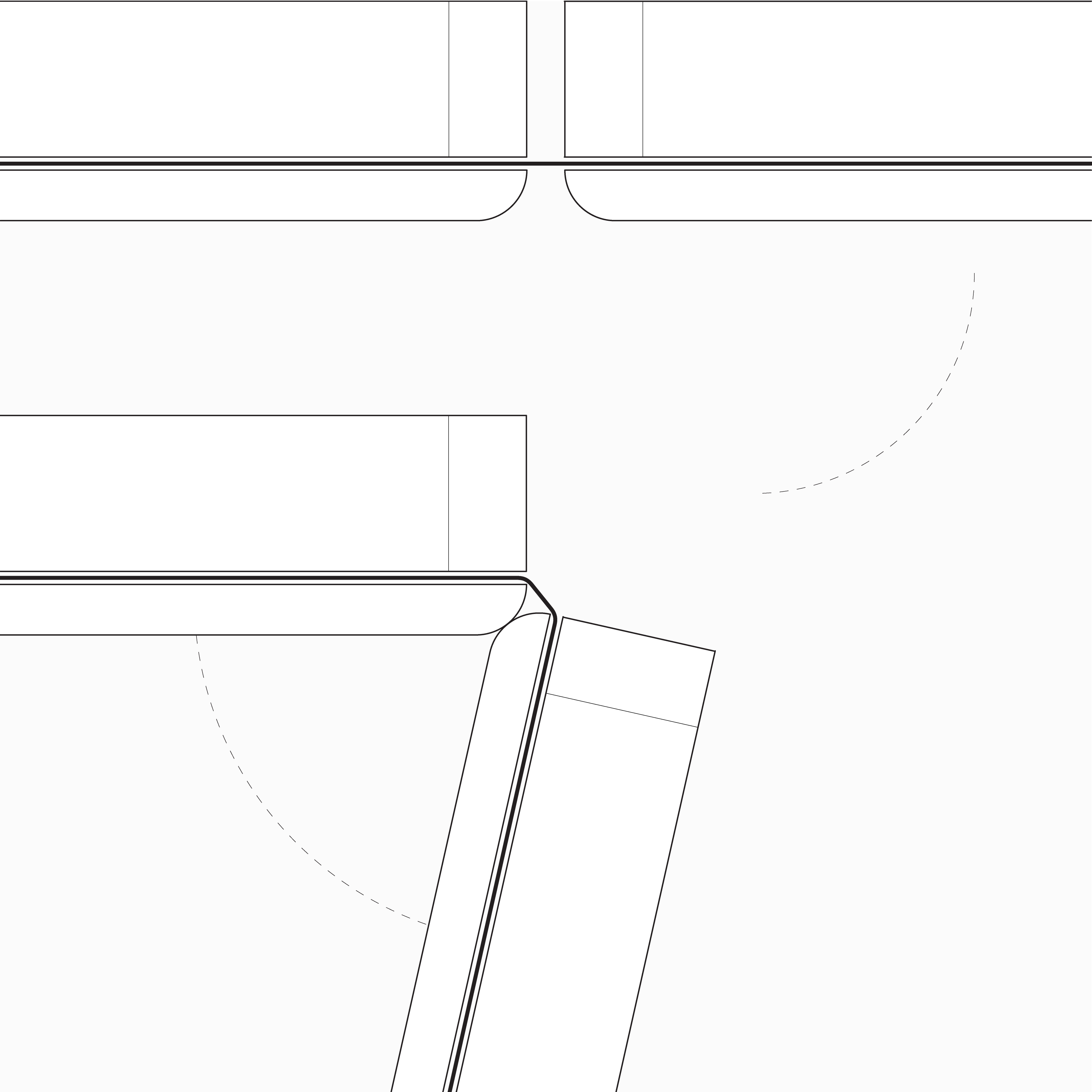

Tile begins with a tessellation of squares and triangular forms which can then be folded three-dimensionally. The approachTil permits fabrication from plastic sheet material with very little waste. The design sandwiches a flexible membrane between rigid plastic panels to generate a collapsible model stand. Embedded magnets permit the stands to be easily unfolded and flat-packed for storage. The unique faceted geometry allows for stacking and rotating the stands for various modes of display.

An initial prototype used HDPE and acrylic panels sandwiching a continuous neoprene sheet. Drawbacks included heaviness, lack of UV-protection, deflection, and adhesion issues. Following materials research, cost analysis, joint and adhesion testing, and geometric studies, production of a new prototype offered a more lightweight, UV-resistant, and rigid solution through the lamination of four types of plastic: High Density Polyethylene (HDPE), 1680 Denier Ballistic Nylon (a synthetic polymer), Kydex 100 (an acrylic-polyvinyl chloride composite), and a 3M Adhesive Transfer Tape (a proprietary thermoplastic).